Brisbane Airport Assets Management

Queensland Sugar Limited (QSL) operate a total of 15 bulk sugar storage sheds located at Bundaberg, Mackay, Townsville, Lucinda, Mourilyan, and Cairns. 12 of the sheds’ roofs were originally clad primarily with “Galbestos”, and the product is approaching the end of its service life.

Ranbury is, without doubt, our trusted project advisor – a company of exceptional integrity who bring clear insight to complex projects and draws on their breadth of experience to resolve them creatively.

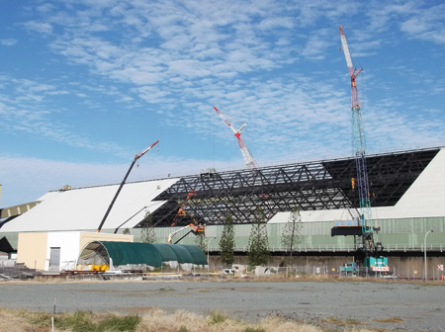

Martin SassenbergRanbury engaged in a program of works to replace the cladding with a new aluminium roof cladding across the 12 bulk storage sugar sheds.

In addition, structural strengthening works are being undertaken to the roof purlins, trusses, end walls and roller doors. Apex walkways are also being refurbished, replaced or added, depending on the existing arrangement and condition.

The bulk storage sugar sheds range in length from approximately 175m to 330m long, with a typical width of 46m and an Apex height approximately 25m, and a roof pitch at 34 degrees.

Ranbury was initially engaged by QSL as Procurement Manager and Superintendent’s Representative for the first project on Mackay Shed No.2. The role was extended to Project Manager for the second project on Mackay Shed No. 3, and further, to include the Superintendent’s role for the fourth project, Cairns Shed No.2 and Mourilyan Shed 1. These latter roles include Design and Procurement Management for each project.

The works involve a combination of high-risk activities such as asbestos removal, and working at heights, on a 34 degree pitch roof, within operational terminals.

Depending on how many storage sheds are at each terminal, and the specific requirements for storage and shipping, the sheds are only empty (or partially empty) for a short period. The works are being undertaken predominantly in the tropics and are subject to the wet season and cyclones between November and April. With cane crushing typically commencing in June, construction completion dates were critical to ensuring smooth operations were maintained.

The works involve a combination of high-risk activities such as asbestos removal, and working at heights, on a 34 degree pitch roof. As part of the contractor procurement process alternate systems were considered, and the current contractor is using a roof access system that is supported on top of the purlins. The system has not been used on such a steep pitch roof before.